Material Change in Illbruck Expanding Foams: Impact on Door & Window Sealing

Sealing windows and doors should be a priority for any project - without this element being completed effectively, environments are left open to drafts, which can lead to a higher heating bill.

Effective installation provides customers with a home or residential building that’s more energy-efficient, durable in the long term, and more comfortable with protection from the surrounding environment.

Illbruck impregnated expanding foams have long been trusted for performance, but recent material changes have meant that all impregnated foam suppliers will be required to review and revalidate product performance. This change is a requirement faced across the industry; and in line with illbruck’s proactive approach and long-standing reputation for quality, the process has already been completed. This article explores what those changes mean and guides you in selecting the correct TP Tape for your project.

What are illbruck Impregnated Expanding Foams?

Impregnated expanding foams are a trusted solution in modern construction, offering excellent performance and easy installation. They are designed primarily for external weather sealing in construction, widely used for window and door sealing joints. A weathertight barrier is created, which protects building joints from harsh weather and environmental exposure. illbruck’s TP Tapes are designed to meet the performance requirements of either 450 Pa or 600 Pa. These foams are pre-compressed into a roll, which expands during application, providing airtightness, weathertightness, and acoustic insulation to a gap.

What does the material change mean?

- Improved Durability: The new TP Tape formulations provide windows and door seals with enhanced resistance to both UV and moisture

- Environmental Considerations: Updated materials may reduce Volatile Organic Compounds (VOCs) emissions, which are made from gaseous, liquid, and solid chemicals. VOCs particularly impact the quality of air within an indoor space, so providing the highest level of protection to decrease these levels is highly important

- Compatibility: The change brings better adhesion, which allows for a stronger bond between TP Tape and modern construction materials

- Better Expansion Control: When applied, the material expands more consistently, providing an equal, reliable seal.

What is the impact on Door & Window Sealing?

TP Tapes can provide a range of benefits to window and door sealings. The performance of illbruck’s TP Tapes ensures that end users experience high-performance sealings that provide the very best protection for:

- Airtightness - The enhanced sealing reduces drafts and heat loss

- Moisture Protection - Prevents water ingress, protecting frames and walls

- Noise Reduction - Improved acoustic insulation for quieter interiors

- Longevity - Extended lifespan reduces maintenance costs.

With this understanding of illbruck’s TP Tapes, the next critical question becomes: How do you choose the correct TP Tape for your project?

Assessing the size of the sealing gap that needs to be filled is important as a foundational starting point. Without knowing the measurement of the gap, it’s unlikely that the correct TP Tape size will be selected – and if the right size is not used, then the seal won’t be protected from moisture ingress and noise, etc.

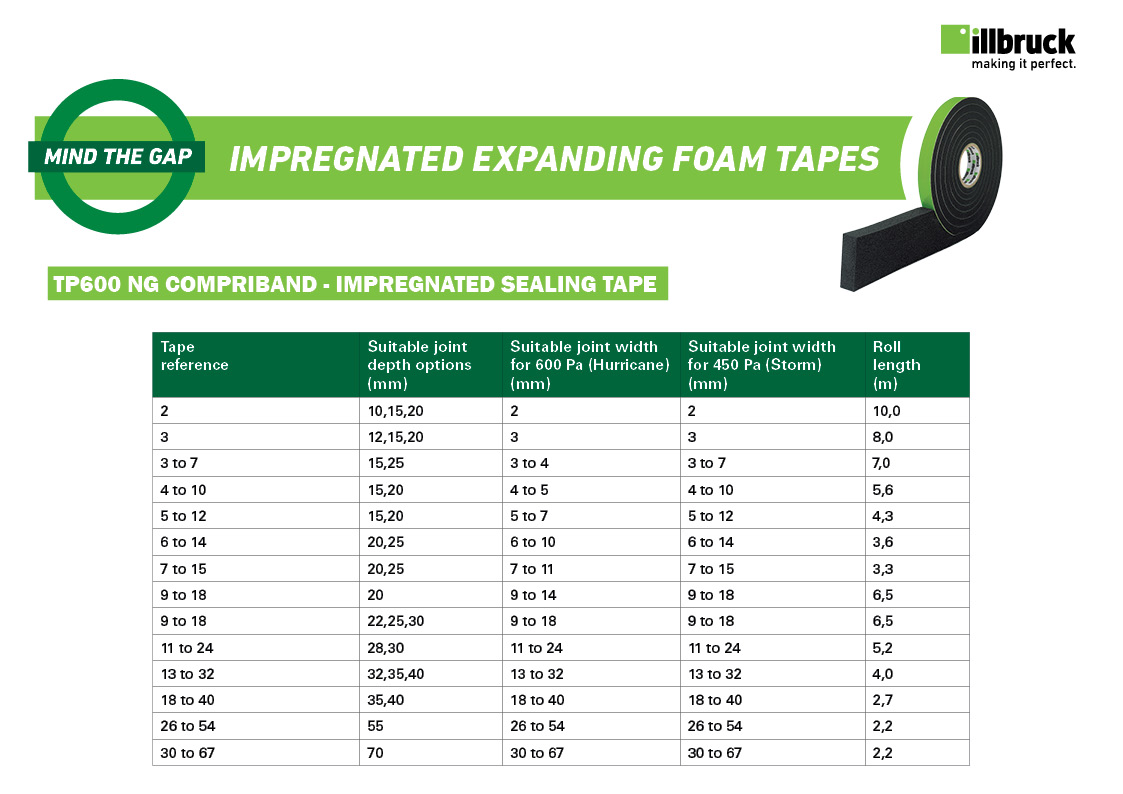

TP Tapes expand to a range of different sizes; the chart below (see fig. 1) shows the new sizes within the range and the size of gap they can be used for installation. If there is any doubt which size should be used, the illbruck technical team are able to support by contacting them here.

With any construction project, it is important to adhere to building standards - it’s no different when working with door and window seals. Ensuring a project is compliant with local energy efficiency codes should be a key priority when installing seals for windows and doors. Conducting this step ensures that the best results in better insulation, lower energy loss, and long-term performance are achieved.

When it comes to the application of illbruck’s TP Tapes, installers can expect ease of application because the pre-compressed sealing tape expands consistently and reliably while conforming to all undulations within a seal. Over the TP Tape’s lifetime, it will continuously contact and expand to accommodate any movement whilst remaining weathertight.

What are the benefits of using TP Tape?

- Faster installation compared to traditional foams

- Cleaner application with minimal waste

- Consistent performance across varying temperatures

- Sustainable choice for eco-conscious projects.

What Pressure and Stress can illbruck TP Tapes withstand?

illbruck’s TP Tapes range is now available in two performance options: 450 Pa and 600 Pa. ‘Pa’ refers to the metric of pascals, which measures the amount of pressure and stress being applied to a surface.

- 450 Pa (Protection from Storm Force 60mph winds (Beaufort scale 10) – Is fully compliant with UK industry and regulatory standards, suitable for the vast majority of applications.

- 600 Pa (Protection from Hurricane Force >70mph (Beaufort scale 12) – Enhanced weather resistance for extreme conditions such as high-rise or coastal projects. While not a UK legal requirement, this option provides added assurance where exposure is highest.

Practical Tips for Builders & Architects

When installing illbruck’s TP Tapes, it is important to follow the criteria listed below to allow for the very best application.

- Always store TP tape in cool, dry conditions before use

- Match tape expansion range to joint width

- Combine with other sealing solutions for maximum efficiency

- Test samples before large-scale application.

The material change in Illbruck impregnated expanding foams represents a step forward in sealing technology. By understanding these updates and carefully choosing the right TP Tape, builders and architects can ensure airtight, durable, and efficient construction.

Steve Wild, illbruck Technical Consultant, said, ‘The updated NG range consolidates the highest performance which illbruck products have provided for over 30 years as market leader and with BBA accreditations in support. We have been proactive in ensuring compliance with the more onerous global regulations, including REACH and PFAS standards. Whether for domestic or high-end commercial window sealing, the Compriband NG range provides complete peace of mind and ensures projects meet all legal and performance requirements.’

iIlbruck’s TP Tapes are redefining installation standards by offering a faster, cleaner, and more sustainable alternative to traditional foams. Their simple application results in minimal waste and consistent performance, making them ideal for modern construction projects.

Leading the range is the TP600 NG Compriband Impregnated Sealing Tape, which delivers up to 15 years of proven performance. As a BBA approved product and a key component of the illbruck i3 system, the TP600 NG provides reliable sealing protection of up to 600 Pa, making it a trusted choice for applications where durability and airtightness are essential. Steve Pendegrass, Head of Distribution Sales, said, ‘I am proud to work for a company that continually strives to improve what is already the best product solution. By making the changes Illbruck have made to their impregnated tape products, our customers can have absolute confidence that their buildings are sealed to the correct weathertightness and that this seal will last for many years to come.’

Find out more about the range here: https://www.illbruck.com/en-gb/products-systems/product-overviews/impregnated-foam-tapes-weatherproof-acoustic-sealing-illbruck-uk/

If you have any questions about illbruck’s TP Tapes range, contact our technical team. https://www.illbruck.com/en-gb/get-in-touch/contact-us/