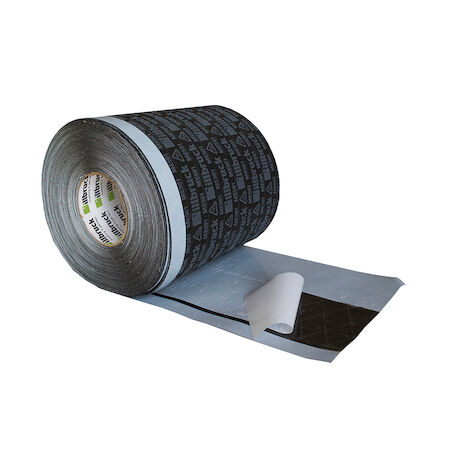

ME501 Duo Window Membrane HD

Class W1 Window Sealing Membrane (EPDM Alternative)

ME501 is a high strength, tear resistant membrane made from polyethylene copolymer film with non-woven fabric. It can be applied before or after window installation to suit on-site details and programming. It is also available with gasket options for fixing to window profiles. The product meets the recommendations of the RAL Quality Assurance Association for windows and doors. Successfully tested by MPA Hannover to EN1026 (airtightness) & EN1027 (weathertightness). The membrane is attached to the window with SP525 adhesive, enhanced ‘acrylic adhesive +’ strip, or integral gasket and to the construction reveal material with SP525 adhesive. Self adhesive version (ME501VV) also available.

.jpg)

.jpg)

Usage/purpose

ME501 provides a high performance seal to the perimeter joint between the window/curtain wall and the construction reveal. Due to the intelligent, variable vapour permeability (sd value), when used in an internal UK (warm) environment, it will be vapour-tight, and when used in an external UK (cold) environment it will be vapour open. This means that the membrane is suitable for interior and exterior use providing an air-tight and weather-tight seal whilst always complying with inside tighter than outside principles.

The product meets the recommendations of the RAL Quality Assurance Association for windows and doors. Successfully tested by MPA Hannover to EN1026 (airtightness) & EN1027 (weathertightness). The membrane is attached to the window with SP525 adhesive, enhanced acrylic adhesive + strip, or integral gasket and to the construction reveal material with SP525 adhesive.

- Complies with principle of ‘inside tighter than outside’ in order to facilitate efficient vapour control

- BBA accredited alternative to EPDM in many applications

- Excellent drying potential (due to the membrane’s vapour permeability) avoiding mould growth and physical damage

- UV stable - will tolerate up to 12 months direct exposure prior to covering

- Fully compatible with illbruck Building Protection Membranes

- Weathertight against driving rain to 1200 Pa

- ME501VV self adhesive version also available

| ME501 Installation of illbruck Membranes to Windows and Doors Application Instructions (en-GB).pdf | Application Instructions | |

| Paste_adhesive_membrane_installation_guide_210325_Issue4.pdf | Application Instructions | |

| Illbruck Compatibility Test Summary Sheathing Boards Issue 2 | Application Instructions | |

| ME501 and SP525 Method Statement (en-GB).pdf | Remedial Method Statements | |

| ME501 Safety Data Sheet (en-GB).pdf | Safety Data Sheets | |

| Site Water Tightness Testing Guidance 2021 (en-GB).pdf | Technical Guidance Document | |

| ME500_ME501 Application Advice For Low Temps Technical Advice (en-GB).pdf | Technical Guidance Document | |

| ME501 Advice on Low Temperature Conditions Technical Advice (en-GB).pdf | Technical Guidance Document | |

| ME508 and ME501 Duo Window Membranes BBA Certificate (en-GB).pdf | Test / Certification Document | |

| ME501 Technical Data Sheet (en-GB).pdf | TDS | |

| ME501 VV Technical Data Sheet (en-GB) 23-10-24.pdf | TDS |

.jpg)

.jpg)